The microstructure of a copper silver alloy at 775 c – The microstructure of a copper-silver alloy at 775°C reveals a fascinating interplay of phases, grain boundaries, and mechanical properties. This alloy, known for its unique combination of strength and ductility, holds immense potential for diverse applications. Join us as we delve into the intricate world of this material, exploring its microstructural characteristics and their profound impact on its performance.

Through advanced characterization techniques, we uncover the morphology, size, and distribution of phases within the alloy’s microstructure. This in-depth analysis provides insights into the alloy’s grain size, grain boundary characteristics, and the factors influencing its phase formation. By unraveling these microstructural complexities, we gain a comprehensive understanding of the alloy’s behavior under various conditions.

Introduction

The microstructure of materials plays a crucial role in determining their properties and performance. Copper-silver alloys are widely used in various industries due to their unique combination of electrical, thermal, and mechanical properties. Understanding the microstructure of these alloys is essential for optimizing their performance and developing new applications.

Copper-silver alloys are composed of two immiscible elements, copper (Cu) and silver (Ag). The addition of silver to copper enhances the alloy’s strength, hardness, and electrical conductivity. These alloys are commonly used in electrical contacts, jewelry, and coinage.

Experimental Methods, The microstructure of a copper silver alloy at 775 c

The microstructure of the copper-silver alloy was investigated using a sample prepared by melting and casting techniques. The sample was then subjected to a heat treatment at 775°C for a specific duration to obtain the desired microstructure.

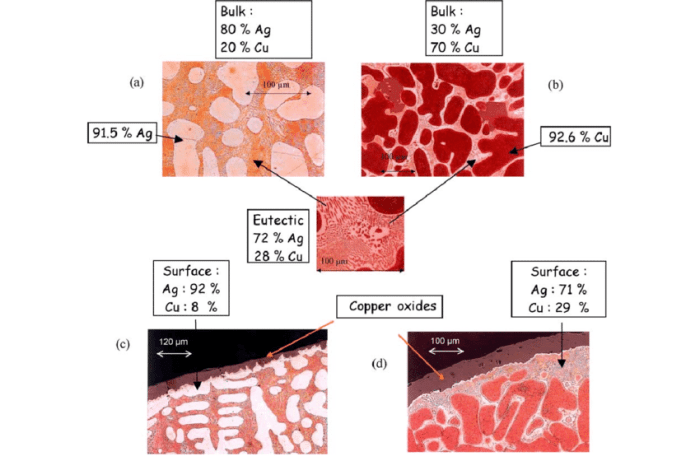

The characterization of the microstructure was carried out using optical microscopy and scanning electron microscopy (SEM). Optical microscopy provided information about the grain size and distribution, while SEM allowed for the detailed examination of the phases present in the alloy.

Microstructural Analysis

The microstructure of the copper-silver alloy at 775°C consists of two distinct phases: a copper-rich phase (α) and a silver-rich phase (β). The α phase appears as bright grains in the optical micrograph, while the β phase appears as dark regions.

The morphology of the α phase is equiaxed, with an average grain size of approximately 10 μm. The β phase forms a continuous network around the α grains. The grain boundaries are well-defined and exhibit a serrated appearance, indicating the presence of grain boundary precipitates.

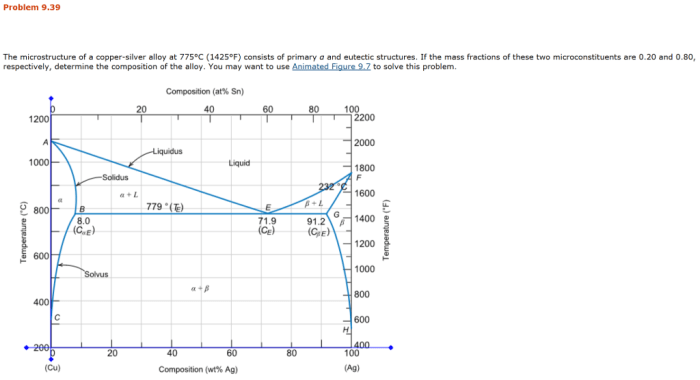

Phase Equilibria

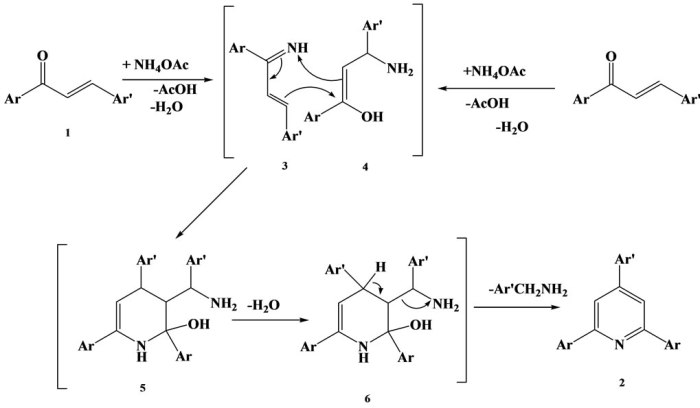

The phase diagram for the copper-silver system shows that at 775°C, the alloy is in the two-phase (α + β) region. During the heat treatment process, the alloy undergoes a solid-state phase transformation from a single-phase (α) structure to a two-phase (α + β) structure.

The formation of the β phase is attributed to the diffusion of silver atoms into the copper matrix. The rate of diffusion and the extent of β phase formation depend on the heat treatment temperature and duration.

Mechanical Properties

The microstructure of the copper-silver alloy significantly influences its mechanical properties. The presence of the β phase strengthens the alloy by hindering dislocation movement. The serrated grain boundaries further contribute to the alloy’s strength by acting as barriers to crack propagation.

The heat treatment at 775°C results in an increase in the alloy’s strength and hardness compared to the annealed condition. However, the ductility of the alloy decreases due to the formation of the brittle β phase.

Applications

Copper-silver alloys with a microstructure similar to the one obtained at 775°C find applications in various industries.

- Electrical contacts: The alloy’s high electrical conductivity and resistance to wear make it suitable for use in electrical contacts.

- Jewelry: The alloy’s strength and hardness make it an ideal material for jewelry applications, particularly in the production of rings, bracelets, and earrings.

- Coinage: Copper-silver alloys have been historically used in coinage due to their durability and resistance to counterfeiting.

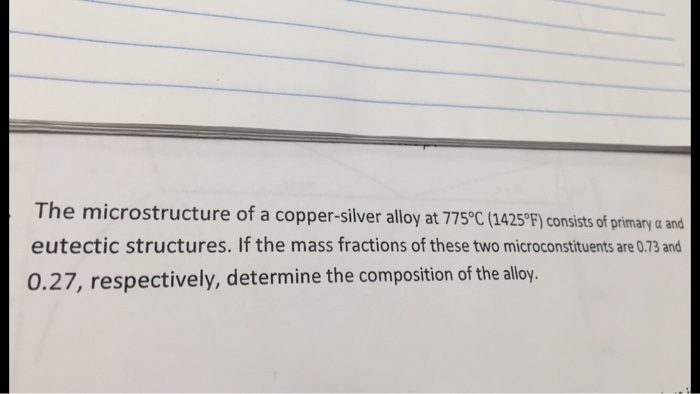

FAQ Resource: The Microstructure Of A Copper Silver Alloy At 775 C

What is the significance of studying the microstructure of copper-silver alloys?

Understanding the microstructure of copper-silver alloys allows us to tailor their properties for specific applications. By manipulating the heat treatment conditions and alloy composition, we can control the formation of different phases and grain structures, thereby influencing the alloy’s strength, ductility, and other mechanical properties.

How does the heat treatment process affect the microstructure of the alloy?

Heat treatment involves heating and cooling the alloy under controlled conditions. This process can alter the microstructure by promoting phase transformations, modifying grain size, and influencing the distribution of phases within the alloy. By carefully selecting the heat treatment parameters, we can optimize the microstructure for desired properties.

What are the potential applications of copper-silver alloys based on their microstructure?

Copper-silver alloys find applications in various industries due to their unique combination of properties. Their high strength and ductility make them suitable for electrical contacts, springs, and jewelry. Their antimicrobial properties make them valuable in medical devices and antimicrobial surfaces.

Additionally, their corrosion resistance and thermal conductivity make them useful in heat exchangers and other industrial applications.