Montmorillonite k10 clay boiling point – The boiling point of montmorillonite K10 clay, a topic of considerable scientific and industrial interest, offers a gateway to understanding the unique characteristics and diverse applications of this remarkable material. This exploration delves into the physical and chemical properties of montmorillonite K10 clay, examining its boiling point and its implications for various industries.

Montmorillonite K10 clay, renowned for its exceptional properties, finds widespread use in numerous sectors, including ceramics, pharmaceuticals, and environmental remediation. Its boiling point plays a crucial role in determining its suitability for specific applications, influencing factors such as thermal stability and processing parameters.

Montmorillonite K10 Clay Properties

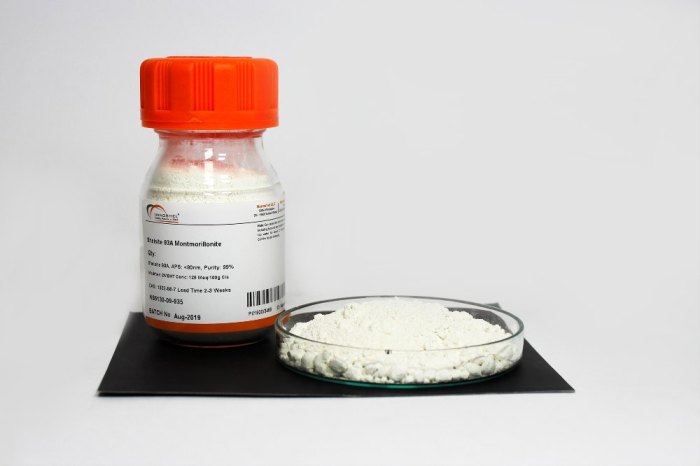

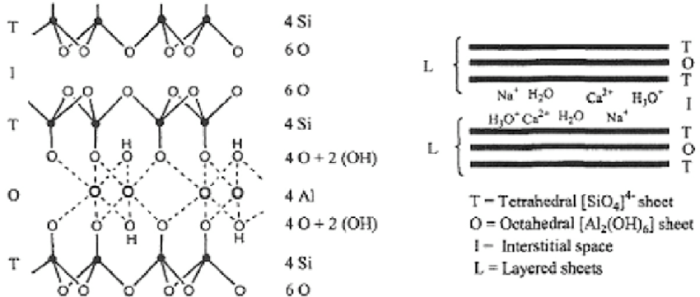

Montmorillonite K10 clay is a natural mineral with a unique layered structure and exceptional properties. It is composed primarily of hydrated aluminum silicate and has a high surface area and cation exchange capacity.

Physically, montmorillonite K10 clay is soft, fine-grained, and has a high water absorption capacity. It swells when hydrated, forming a gel-like substance that can absorb up to several times its own weight in water. Chemically, it is composed of silicon, aluminum, oxygen, hydrogen, and various other elements in trace amounts.

The table below compares the properties of montmorillonite K10 clay to other types of clays:

| Property | Montmorillonite K10 Clay | Kaolinite | Bentonite |

|---|---|---|---|

| Chemical composition | Hydrated aluminum silicate | Hydrated aluminum silicate | Hydrated sodium aluminum silicate |

| Structure | Layered | Layered | Amorphous |

| Surface area (m2/g) | 700-800 | 10-20 | 50-100 |

| Cation exchange capacity (meq/100 g) | 80-150 | 5-15 | 50-100 |

| Water absorption capacity (%) | 100-200 | 50-100 | 150-250 |

Montmorillonite K10 Clay Applications

Montmorillonite K10 clay has a wide range of applications in various industries due to its unique properties. Some of its most common uses include:

- Drilling fluids:As a component of drilling fluids, montmorillonite K10 clay helps to control viscosity, lubricate the drill bit, and prevent borehole collapse.

- Foundry binders:In foundries, montmorillonite K10 clay is used as a binder in the production of molds and cores for metal casting.

- Paper industry:In the paper industry, montmorillonite K10 clay is used as a filler and coating material to improve paper quality and printability.

- Ceramics:Montmorillonite K10 clay is used in the production of ceramics, such as tiles, pottery, and sanitary ware, due to its plasticity and ability to withstand high temperatures.

- Cosmetics:Montmorillonite K10 clay is used in cosmetics as a thickener, stabilizer, and opacifier.

- Pharmaceuticals:In the pharmaceutical industry, montmorillonite K10 clay is used as a carrier for drug delivery systems.

- Water treatment:Montmorillonite K10 clay is used in water treatment processes as an adsorbent for removing impurities.

- Agriculture:In agriculture, montmorillonite K10 clay is used as a soil amendment to improve soil structure and water retention.

Helpful Answers: Montmorillonite K10 Clay Boiling Point

What is the significance of the boiling point for montmorillonite K10 clay?

The boiling point of montmorillonite K10 clay is crucial for determining its thermal stability and suitability for high-temperature applications. It influences factors such as processing conditions, product quality, and safety considerations.

How does the boiling point of montmorillonite K10 clay compare to other types of clays?

Montmorillonite K10 clay generally has a higher boiling point compared to other types of clays due to its unique structural and compositional characteristics. This higher boiling point contributes to its enhanced thermal stability and resistance to degradation at elevated temperatures.

What are the potential applications of montmorillonite K10 clay based on its boiling point?

The high boiling point of montmorillonite K10 clay makes it suitable for applications requiring thermal stability, such as refractory materials, high-temperature coatings, and insulation. It is also used in industries where resistance to高温 is essential, such as aerospace and automotive.